The Moment Everything Changes

It’s 4:00 PM on a Friday. You’re thinking about the weekend. Then your phone rings.

A supplier just flagged a contaminated batch. By Monday morning, you need a list of every customer who received product from Lot #882.

The FDA maintains a running list of pet food recalls and advisories, and the pattern is clear: companies that can’t trace fast enough face the worst outcomes.

Your first move? Opening three different Excel files. One’s on the shared drive. One’s on someone’s desktop. And one… you’re pretty sure exists, but you’ll need to call the warehouse manager to find it. He’s already left for the day.

In fact, this is the moment most companies discover their lot tracking is broken.

Recalls aren’t just logistical headaches. They create financial, reputational, and regulatory cascades that move fast and leave almost no room for error. Industry estimates put the average direct cost of a food recall at $10 million. And that’s just the direct costs — retrieval, disposal, notifications. It doesn’t include the lawsuits, the lost accounts, or the brand damage that lingers for years.

When traceability is weak, those costs climb even higher. Why? Because you end up recalling more product than necessary. You can’t isolate the problem, so you pull everything that might be affected. That’s expensive. And it’s avoidable.

If your first instinct during a recall is to start hunting through spreadsheets, you’ve already lost the critical early window of control.

What Regulators Actually Expect (And How Fast)

The rules have changed.

FSMA 204 (the FDA’s Food Traceability Final Rule ) requires companies to provide electronic, sortable traceability data within 24 hours of a request. That’s not a soft deadline. That’s not “get back to us when you can.” That’s 24 hours. Including weekends. If FDA calls at 5:00 PM Friday, you have until 5:00 PM Saturday.

Now, FSMA 204 specifically targets high-risk foods. But the expectation it sets ripples outward. Auditors, insurers, and major retailers are already using it as a benchmark for evaluating all food distributors. If you’re distributing pet food, you’re tracking ingredients from multiple suppliers, batches produced on different dates, and products shipped to retailers, vets, and direct-to-consumer channels. The complexity adds up fast.

The burden of proof is on you. When someone asks for traceability data, they expect verifiable, timestamped records that are immediately retrievable. Not “give us a few days to pull it together.” Not “we know where it is, we just need to find it.”

Good intentions don’t satisfy an auditor. Only verifiable, timestamped data does.

Why Spreadsheets Fail Under Recall Pressure

Spreadsheets are familiar. They’re flexible. Everyone knows how to use them.

They’re also fragile under stress.

Studies of operational spreadsheets consistently find that over 90% contain errors. Not complicated spreadsheets built by amateurs. Regular, everyday business spreadsheets. The kind your team uses right now.

In normal operations, a small error might not matter much. But during a recall, a single incorrect lot reference can mean over-recalling safe product or missing affected customers entirely. Both are expensive. One is dangerous.

Manual data entry. Someone types “Lot 882” instead of “Lot 822.” Nobody catches it. Six months later, that typo determines whether a customer gets notified or not.

Multiple versions. The warehouse has one file. Accounting has another. Sales exported their own copy three weeks ago and added some columns. Which one is the truth? Nobody’s entirely sure.

The linking problem. Connecting supplier lots to internal batches to outbound shipments requires hopping between files, cross-referencing dates, and hoping someone kept good notes. Under time pressure, this falls apart fast.

Spreadsheets are fine for storing data. They’re catastrophic for retrieving the right data under pressure.

The Hidden Risk of “We Can Figure It Out If It Happens”

I get it. Recalls feel rare. Theoretical. Something that happens to other companies.

So the plan becomes: “If it happens, we’ll figure it out.”

What matters isn’t likelihood. It’s impact.

A recall doesn’t just test your systems. It tests your leadership, your brand trust, and your operational maturity, all at once, under a deadline, with regulators and customers watching.

And if your traceability depends on one person who knows where the files are and how the process works? You don’t have a system. You have a single point of failure.

I’ve seen this pattern over and over. The warehouse manager who’s been there 15 years and “just knows” where everything is; the office manager who built the spreadsheet system and is the only one who understands the formulas; the IT person who retired two years ago and took all the workarounds with them.

These aren’t bad employees. They’re good employees in a bad structure. And when they’re on vacation, or sick, or gone, the whole thing stops.

For food distributors, this risk compounds quickly. You’re not just tracking finished goods. You’re tracking ingredients from multiple suppliers, production batches across different dates, and shipments going to retailers, foodservice, and maybe direct-to-consumer. Every handoff is a place where traceability can break. The question isn’t whether you’ll ever face a recall. It’s whether you’ll be ready when you do.

What Proper Lot Tracking Actually Looks Like

Effective lot tracking isn’t about better spreadsheets. It’s not about more reports or extra columns or color-coded tabs.

It’s about how work happens every day.

When lot tracking is built into your system properly, traceability isn’t a separate task. It’s just how things work.

Every receive is tied to a lot. When product comes in, you capture the lot number as part of receiving. Not written on a sticky note. Not added to a spreadsheet later. It’s in the system before the product hits the shelf.

Every pick is tied to a lot. When an order ships, the system knows exactly which lots went out the door. Not “probably from that pallet we got last week.” Exactly which lots.

Every transaction is linked. Supplier lot → internal batch → customer shipment. You can query the unbroken chain. When someone asks “who got Lot 882?” the answer takes minutes, not days.

The difference shows up during a mock recall. Industry best practice is completing a traceability exercise, identifying all affected customers and products, in 2-4 hours. Major retailers like Chewy expect even faster. If your mock recall takes three days of digging through files and calling the warehouse, that’s not a drill. That’s a warning.

The goal isn’t recording information after the fact. It’s systems that enforce traceability as work gets done.

Why This Is a System Decision, Not a Process Fix

You can’t train your way out of structural gaps.

I’ve seen companies try. They create checklists. They add steps. They tell the warehouse team to “be more careful” about writing down lot numbers. They hold meetings about the importance of data accuracy.

And for a few weeks, it works. Then someone gets busy. A step gets skipped. The checklist gets ignored because there’s a truck waiting. And you’re right back where you started.

The problem is rarely the software itself. It’s the workflows built around it. I dig into this more in Stop Blaming the System: The Messy Truth About Bad Workflows.

It’s not the people either. It’s that manual systems depend on perfect human behavior, every time, under pressure. That’s not realistic. Well-designed systems act as gatekeepers. If the lot number is missing, the receive can’t be completed. If the pick isn’t tied to a lot, the shipment can’t go out. The system doesn’t allow the gap to exist in the first place.

This is the difference between “we have a process” and “we have a system.”

Processes depend on people remembering. Systems enforce the rules automatically.

The manual approach scales by adding people: more checkers, more oversight, more meetings about why things fell through the cracks.

Automation scales by adding consistency. The hundredth transaction is tracked exactly like the first.

When a recall hits, you don’t want to be hoping everyone followed the process. You want to know the system made it impossible not to.

The Cost of Waiting Is Usually Invisible Until It Isn’t

Of course, delaying traceability improvements often feels reasonable. The system works. Nobody’s complained lately. There are bigger fires to fight.

But then something shifts, and suddenly the cost becomes very visible.

Retailer audits. Major retailers and chains like Chewy, Petco, and large grocery buyers increasingly audit supplier traceability before signing or renewing contracts. Excel-based processes raise red flags. That doesn’t mean an automatic rejection, but it does mean harder conversations, more scrutiny, and sometimes lost opportunities you never even hear about.

Insurance Scrutiny. Product recall and liability insurers factor traceability controls into their assessments. Weak documentation can mean higher premiums or, in some cases, difficulty getting coverage at all.

The question you can’t answer fast enough. There are few harder moments than telling a regulator or a major customer that the data exists, you just need more time to find it. That’s not a confidence-building statement.

The costs of waiting don’t show up on a balance sheet. They show up in the account you didn’t win, the audit that went sideways, and the scramble that could have been avoided.

A Better Time to Learn This Lesson

The best time to evaluate your traceability readiness is when:

- No recall is active.

- No deadline is ticking.

- No one is watching.

Run a mock recall. Pick a random ingredient lot from three to six months ago. See how long it takes to trace it forward to finished products and outward to customers. Document where you got stuck, what took longest, and what required a phone call instead of a report.

If you can do it in under four hours with confidence in the data, then you’re in good shape. If it takes days, or depends on one person who “knows where everything is,” that’s your answer.

The worst time to learn your lot tracking is broken is during your first real recall.

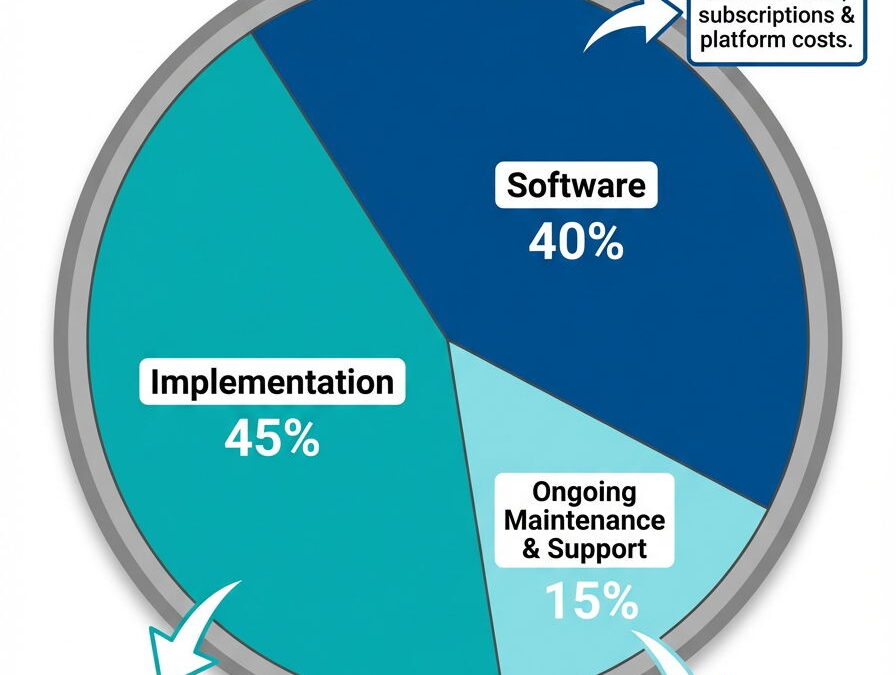

But What About the Cost of Upgrading?

Fair question.

Implementing proper lot tracking typically costs $15,000 to $30,000 in year one, depending on the complexity of your operation and how much cleanup is needed.

That feels substantial until you compare it to the alternatives:

The average food recall costs $10 million or more in direct expenses alone.

Over-recalling even one week’s worth of product because you couldn’t isolate the affected lots can exceed your entire implementation cost.

Retailer and insurance requirements increasingly treat traceability as table stakes, not a nice-to-have.

The real question isn’t whether you can afford to upgrade. It’s whether you can afford the risk of not upgrading.

Let’s Talk About Your Recall Readiness

Are you compliant on paper, or actually ready to respond within 24 hours?

If you’re not sure, let’s walk through your current workflows and see where manual processes might be creating hidden risk. No pressure, no pitch. Just an honest look at where you stand.